The throttling process occurs inside the industrial pipeline system and is used to reduce pressure and speed. It regulates the flow from one point to another, that is, from high pressure to low pressure, and prevents the system performance from degrading. Since throttling is an important part of the industrial field, all throttle valves have throttling functions.

Working principle of throttle valve

The core function of the throttle valve is to limit the flow of fluid, and its working principle is mainly based on changing the flow cross-sectional area to control the flow and pressure of the fluid. The control effect of the throttle valve is closely related to the valve opening. Generally speaking, the smaller the cross-sectional area, the less the flow, and the greater the upstream and downstream pressure difference. But when the critical opening is reached, the blocking flow phenomenon will occur, and the flow tends to be constant at this time.

Types of throttle valves

The throttle valve is designed for throttling, including globe valves, ball valves, butterfly valves, needle valves, diaphragm valves and other valves. Here are three common throttle valves for everyone to discuss.

The globe valve is divided into flange type, angle type, DC type and plunger type. The connection methods include flange connection, threaded connection, welding connection, etc. The structure is simpler than the gate valve and is easy to maintain, but the fluid resistance is large and the opening and closing torque is high. It is suitable for pipeline systems of water, oil, steam, gas and other media, and is widely used in chemical, petroleum, electric power, environmental protection and other fields. However, it is not suitable for media with high viscosity or particles that are easy to precipitate.

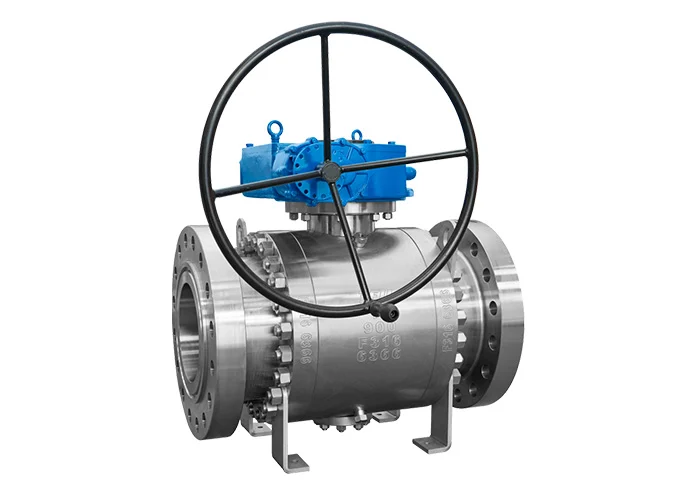

The industrial ball valve is a widely used valve. Its opening and closing parts are spheres, which are driven by the valve stem to rotate 90 degrees around the axis to achieve opening and closing. The ball valve has a simple structure, good sealing performance, small fluid resistance, small driving torque, easy operation, and can be opened and closed quickly. It is suitable for a wide range of media, including water, oil, steam, gas, etc. It is used to cut off, distribute and change the flow direction of the medium in many industrial fields such as petroleum, chemical, electric power, environmental protection, etc. Some of them are designed with V-shaped openings and can also adjust the flow rate.

The butterfly valve is a simple regulating valve that can be used for the switch control of low-pressure pipeline media. Its closing part is a disc-shaped butterfly plate, which rotates around the valve shaft to achieve the purpose of opening and closing. The butterfly valve has the characteristics of small size, light weight, low material consumption, small installation size, fast switching (90° reciprocating rotation), and small driving torque. It is suitable for cutting off, connecting, and regulating the medium in the pipeline. It can be used to control a variety of fluids such as air, water, and steam, and is widely used in large-caliber regulation fields. However, the operating pressure and operating temperature range of the butterfly valve are small, and the sealing is relatively poor.

Application of throttle valve in industry

• Accurate flow control: In many industrial production processes such as chemical, petroleum, and metallurgy, it is necessary to accurately control the flow of various fluids (such as gas and liquid) to ensure the stability of the production process and the consistency of product quality. For example, in chemical reactions, the amount of reactants added is accurately adjusted through the throttle valve so that the reaction proceeds according to the predetermined stoichiometric ratio, thereby improving the purity and yield of the product.

• Regulating pressure: The throttle valve can be used to adjust the pressure in the system to ensure that the equipment and pipelines operate within a safe pressure range. When the system pressure is too high, the throttle valve can reduce the pressure by reducing the fluid channel area and increasing the fluid flow resistance. In the hydraulic system, the throttle valve is used in conjunction with the overflow valve to effectively control the output pressure of the hydraulic pump and prevent the system from being damaged due to excessive pressure.

• Achieve actuator speed control: In hydraulic and pneumatic systems, the throttle valve can control the fluid flow entering the actuator (such as hydraulic cylinder, cylinder), thereby adjusting the movement speed of the actuator. On the automated production line, the throttle valve is used to adjust the movement speed of the cylinder to make the production rhythm more reasonable and improve production efficiency.

If you want to know more about valves, please contact us, and TEJI will have professionals to discuss with you.