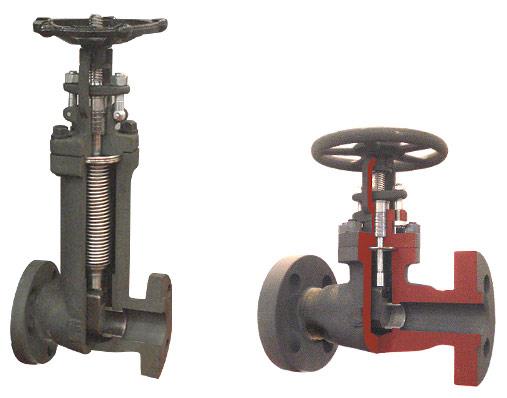

Teji Valve manufactures forged steel bellow sealed gate valves in three kinds bonnet design—Bolted Bonnet, Welded Bonnet and Pressure Sealed Bonnet.

Anfeng Industrial Zone, Oubei Town, Yongjia County, Zhejiang Province

| NPS | Conv. | 3/8″ | 1/2″ | 3/4″ | 1″ | 1-1/4″ | 1-1/2″ | 2″ |

| Full | 3/8″ | 1/2″ | 3/4″ | 1″ | 1-1/4″ | 1-1/2″ | ||

| L | 79 | 79 | 92 | 111 | 120 | 152 | 172 | |

| H(OPEN) | 220 | 220 | 225 | 244 | 321 | 321 | 347 | |

| W | 100 | 100 | 100 | 125 | 160 | 160 | 180 | |

| Weights | Bolted | 3.2 | 3.0 | 4.8 | 7.9 | 11.0 | 16.8 | 25.2 |

| Welded | 3.0 | 2.8 | 4.8 | 7.0 | 9.6 | 13.5 | 20.2 | |

| NO. | Part Name | CS to ASTM | AS to ASTM | SS to ASTM | |

| Type A105 | Type A182 F22 | Type A182 F304 | Type A182 F316(L) | ||

| 1 | Body | A105 | A182 F22 | A182 F304(L) | A182 F316(L) |

| 2 | Disc | A276 420 | A276 304 | A276 304(L) | A276 316(L) |

| 3 | Gasket | Corrugated SS + graphite | SS + PTFE | ||

| 4 | Bonnet Bolt | A193 B7 | A193 B16 | A193 B8 | A193 B8M |

| 5 | Stem | A182 F6 | A182 F304 | A182 F304(L) | A182 F316(L) |

| 6 | Bellow Pipe | SS | |||

| 7 | Bonnet | A105 | A182 F22 | A182 F604(L) | A182 F316(L) |

| 8 | Stem Packing | Flexible Graphite | PTFE | ||

| 9 | Pin | A276 420 | A182 F304 | ||

| 10 | Gland | A276 420 | A182 F304 | ||

| 11 | Gland Eyebolt | A193 B7 | A193 B16 | A193 B8 | A193 B8M |

| 12 | Gland Flange | A216 WCB | A351 CF8 | ||

| 13 | Gland Nut | A194 2H | A194 4 | A194 8 | A194 8M |

| 14 | Bearing Washer | SS | |||

| 15 | Yoke Nut | A276 410 | |||

| 16 | Nameplate | SS | |||

| 17 | Handwheel | A197 | |||

| 18 | H.W.Nut | A194 2H | A194 4 | A194 8 | A194 8M |

| Suitable Medium | W.O.G.etc | W.O.G.etc | HNO3,CH3OOH etc | ||

| Suitable Temp. | -29~425 deg C | -29~550 deg C | -29~180 deg C | ||

NOTE: Other materials are available upon request.

IMPROVEMENTS:

Anfeng Industrial Zone, Oubei Town, Yongjia County, Zhejiang Province

+86-577-67354000

Welcome to Teji Valve Group Co.,Ltd. Get Updates And Stay Connected – Subscribe To Our Newsletter.

on your first order