Ball valves are widely used in various industries, including oil and gas, water treatment and chemical processing. Ball valves are one of the preferred valves in industrial piping systems due to their simple structure and high reliability, especially in situations where quick shut-off or strict sealing is required.

The role of a ball valve is inseparable from the coordinated operation of each component. Understanding the composition of each component of a ball valve is essential to ensure the correct operation and maintenance of the ball valve.

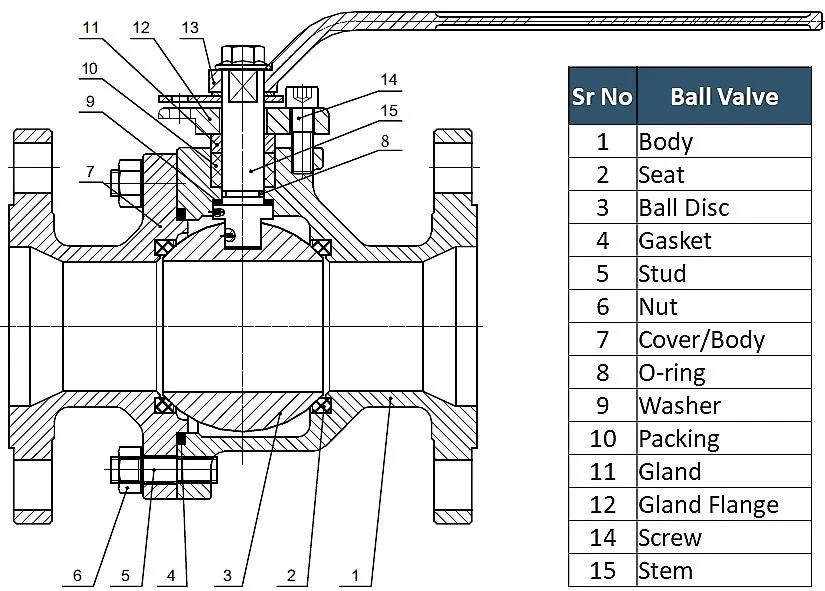

Basic structure of a ball valve

Valve body: As the main structure of the ball valve, it accommodates and supports internal components, provides fluid channels, and is the basic framework of the entire ball valve. The main materials are cast iron, carbon steel, stainless steel, PVC, etc., which can be selected according to different working conditions.

Ball: This is the core opening and closing part of the ball valve, which controls the on and off of the fluid by rotation to achieve the regulation of the flow of the medium. There is a circular through hole inside, which can be rotated 90 degrees to achieve switching. Match the material of the valve body, such as stainless steel, PVC, etc.

Valve stem: One end is connected to the ball, and the other end extends out of the valve body and is connected to the drive device to transmit the driving force and realize the rotation of the ball. The material is usually stainless steel, which has sufficient strength and corrosion resistance.

Valve seat: The main function is to form a seal with the ball to ensure that the ball valve will not leak when the medium is closed. Commonly used materials include polytetrafluoroethylene (PTFE), rubber, etc., which have good sealing and corrosion resistance.

Sealing ring (or sealing ring): Enhance the sealing between the valve seat and the ball, prevent the medium from leaking from the contact point between the two, and further improve the sealing performance of the ball valve.

Valve cover: Used to fix the sealing element and connect with the valve body to protect the internal components and ensure the seal.

Packing: Fill the gap between the valve stem and the valve cover to prevent the medium from leaking along the valve stem to the outside of the ball valve

Auxiliary components

Upper and lower ball covers: Play a certain role in protecting and fixing the ball, and together with the valve body and other components, constitute the overall structure of the ball valve.

Drive device: Provide power for the rotation of the ball, which can be a manual handle, worm gear, etc., or an automatic drive method such as electric, pneumatic, hydraulic, etc., to meet different usage scenarios and control requirements.

Upper bearing and lower bearing: provide support for the rotation of the ball, reduce friction during rotation, and make the ball rotate more smoothly.

Understanding the composition and structure of the ball valve is very helpful for maintaining the ball valve. In addition to regular and large-scale inspections of the ball valve, daily maintenance is also essential. The ball valve can be inspected and maintained from the following three aspects on a daily basis:

Seal inspection and cleaning: Check whether there is leakage at the valve stem seal. If oil stains are found to be accumulated, take immediate measures to prevent the medium from leaking along the valve stem to the outside of the ball valve.

Lubrication of rotating parts: It is recommended to pay attention to the rotating parts of the handwheel every week. If dry friction causes jamming, high-temperature resistant lubricant needs to be injected to ensure smooth rotation of the valve stem.

Anti-rust treatment of valve body: For the valve body exposed to the outside, it is necessary to wipe the surface with anti-rust oil regularly to prevent the valve body from rusting and affecting the service life.

At the same time, standardized operation is also crucial to extend the life of the ball valve. For example, when opening and closing the valve, you must follow the principle of “slow opening and quick closing” to avoid damage to the ball, valve seat and other components caused by too fast or too violent operation, which will affect the sealing performance and service life of the ball valve.

TEJI VALVE GROUP focusing on designing and manufacturing of industrial valves since 1980.TEJI will be your good valve partner.