September 13, 2025

On September 9th, the Gastech Exhibition & Conference, a premier global energy industry event, grandly opened at the Fiera Milano Rho in Milan, Italy. As the world’s largest conference and exhibition for natural gas, liquefied natural gas, hydrogen, climate technology, and energy artificial intelligence, Gastech attracted over 1,000 companies from over 150 countries, occupying over 55,000 square meters of exhibition space and gathering over 50,000 industry experts. TEJI Valve Group showcased its core products, including cryogenic ball valves, and its full lifecycle energy solutions.

As the global energy mix shifts toward cleaner, lower-carbon energy, liquefied natural gas (LNG) is increasingly prominent as a key transition energy source. However, LNG storage and transportation pose severe challenges to valve materials’ low-temperature resistance, sealing reliability, and impact resistance. TEJI Valve’s ultra-low-temperature ball valve addresses industry pain points. It utilizes a Lip-seal seal structure. The Lip-seal combines spring elastic compensation with the excellent low-temperature elastic sealing properties of PTFE. This allows for a tight fit between the valve seat and the ball even under extreme operating conditions of -196°C, ensuring zero leakage and a long service life. We also exhibited specialty valves such as ultra-low-temperature butterfly valves and shear valves, covering the entire supply chain, including oil and gas exploration, refining and processing, and LNG storage and transportation, aiming to provide customers with a “one-stop fluid solution.”

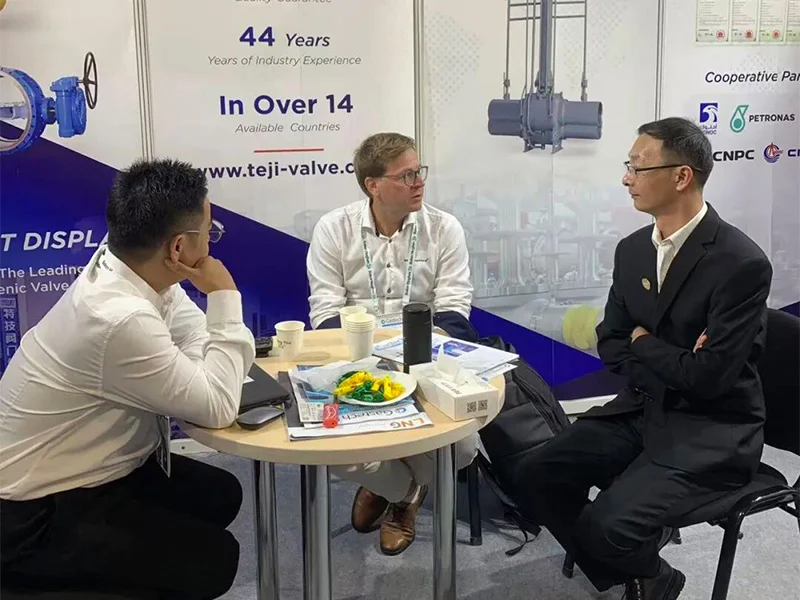

On the first day of the exhibition, the TEJI Valve booth was bustling with visitors, with representatives from energy companies in Italy, Norway, and the Middle East stopping by to negotiate business. The TEJI technical team demonstrated the reliability of ultra-low-temperature valves in extremely cold environments through a combination of technical explanations and product demonstrations.

Following its global strategy, TEJI valves have served over 20 countries and regions worldwide. Its products are widely used by renowned domestic and international companies and projects, including those of CNPC, Sinopec, CNOOC, and oil and gas pipelines and LNG receiving terminals in Russia, Southeast Asia, and the Middle East. Participating in Gastech is not only an international showcase of TEJI’s technological strength, but also an important opportunity to deepen global energy cooperation.